Bonus Content - Paper Aeroplanes!

When I was about 10 or so, my grandma once gave me a copy of a magazine; I'm fairly sure it was a Reader's Digest. Within those pages were the instructions to make a paper aeroplane - I vaguely recall it was some sort of competition winner or record holder. I committed the design to memory, and ever since it's been my go-to design for airborne paper hijinks.

I spent a futile 15 minutes this weekend trying to find some record of it online with the idea of first showing it to some family who were staying this weekend, then secondly of putting it up on Twitter. However, my Google-Fu let me down, so I decided I'd draw up a set of instructions of my own and post them here instead.

If anyone who sees this can find any proper attribution for the design, I'll happily update to include it, but for now, here we go...

- Fold down one of the top corners to its opposite side, make the crease sharp, then unfold.

- Repeat for the other corner.

- Fold horizontally back over, make a nice sharp crease, then unfold again.

- Bring the points all labelled 3 together, which should collapse all the pink area into the shape of the blue triangle.

- Fold up the loose flaps into the shape shown.

- Fold in the the corners again to create a kite shape.

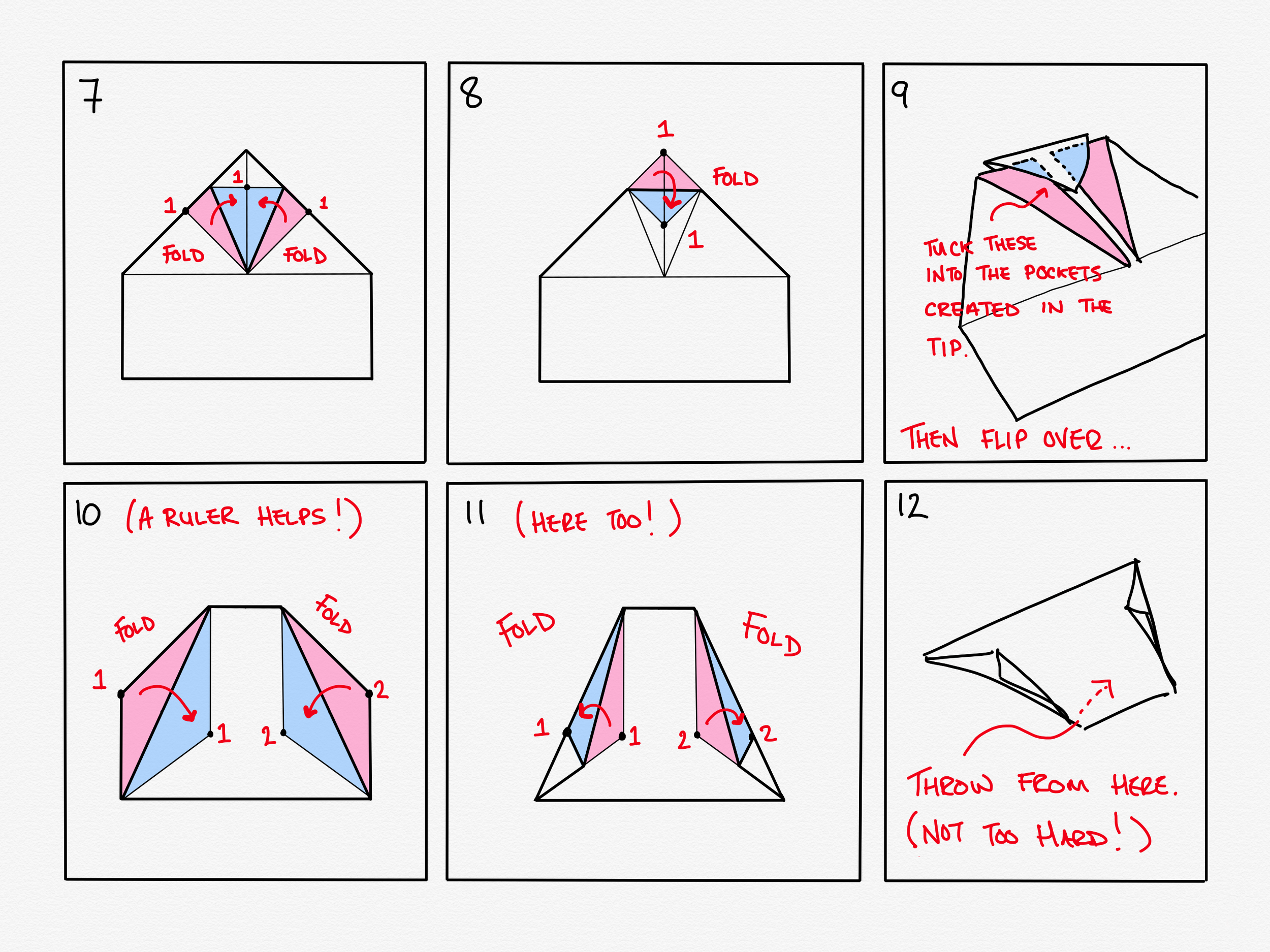

- Step 7 I now realise (much too late to change it) is inexplicably a copy of step 6. You may safely ignore it and move onto step 8.

- Fold down the point as shown.

- This is the tricky bit. Unfold the pink parts - the top ones only - then tuck them into the pockets you find in the tip you folded over on step 8. You might need to bend them a little to get the in, but once you've got them slid in and flattened down then the whole thing will hold itself together solidly.

- Flip the paper over so you're now looking at the top of the plane - all the work you've done so far was on the underside - then make the folds as shown; these will be winglets. To get these folds exactly right it helps to use a ruler*.

- Fold the edges of the winglets back on themselves and then give them a gentle tug so they don't lie too flat to the body of the plane.

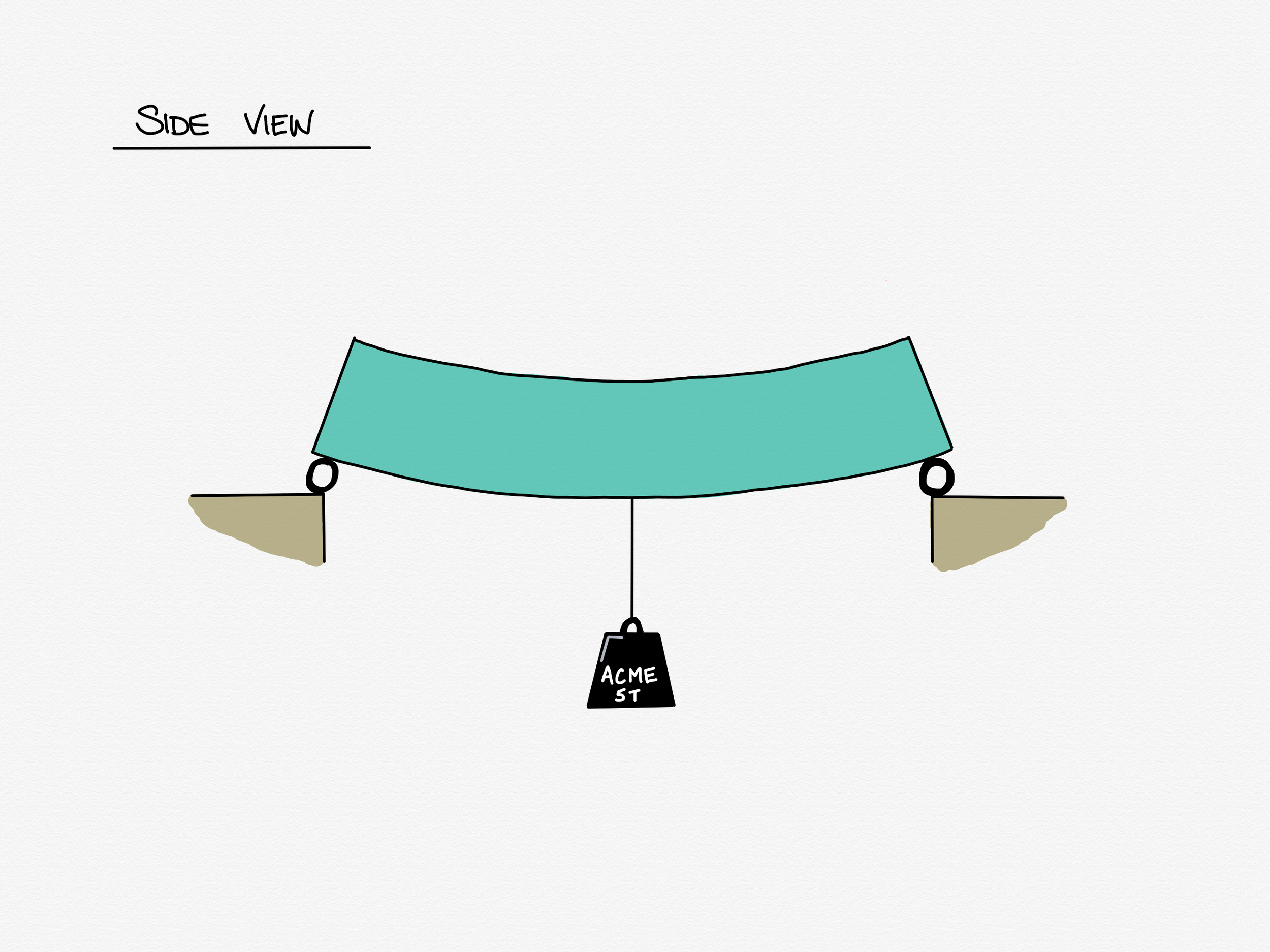

- Hold it by finger and thumb on the little pocket on the underside, and give a throw! It works best if you give it more of a deliberate straight push (a bit like a dart) than a throw.

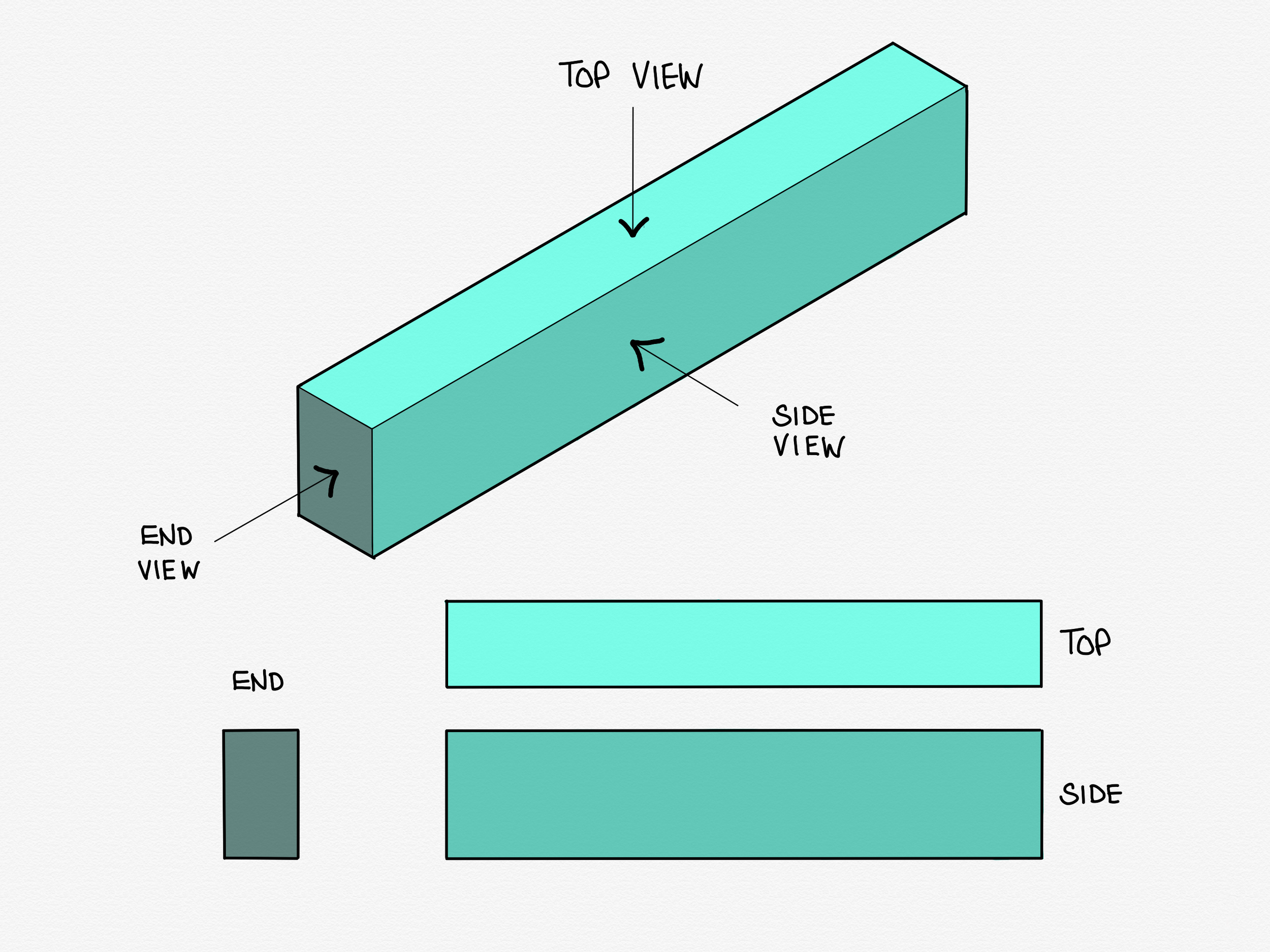

Note: Don't bend it or fold it in half - the whole thing is a wing.

If you want, you can post photos your attempts to follow my hastily compiled instructions to twitter and mention me on @martynpie or you can be a crazy person and email me at martyn@martynpie.com

*I know, I know, rulers again. Sorry.